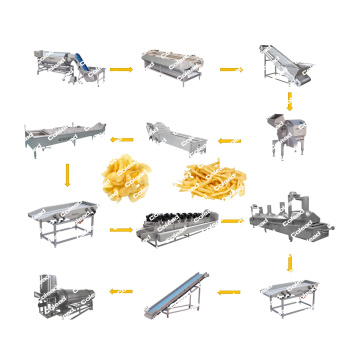

Click on the follow link to find out more information: https://www.colead-tech.com/fried-potato-line/

Company Info

- Company Name: Shandong Colead Intellectualized Food Processing Equipment Co.,LTD

- Representative: Xuejin Chu

- Product/Service: Fresh Cut Processing Line , Vegetable Cutting Machine , Vegetable Processing Machine , Fruit Processing Machine , Salad Processing Line , Palm Dates Processing Line

- Capital (Million US $): USD 1 Million

- Year Established: 2004

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 41% - 50%

- Total Annual Purchase Volume (Million US $): US$2.5 Million - US$5 Million

- No. of Production Lines: 10

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: Dianzi Industrial Park, BoXing County, BinZhou City, Shandong Province, China

- Contact Person: Ms. Evelyn

- Tel: 86--18766632797

Premium Related Products

Other Products

Hot Products

red chilliChinese Peanut KernelLight speckled beans (Long shape)chinese garlic powderchinese navel orangefresh chinese mandarinchinese honey pomelo20kg fresh onionChinese fresh tarofresh apple exporterLatest Low Price Ginger, Yellow Fresh Ginger, New Ginger 2014Chinese chestnut exporter TaianChinese Carrot SupplierYellow Potato Price, Small PackageYa Pear PriceChinese Garlic Packages in Bag or Carton